OVER the previous weeks I have focused on laying the foundation that successful transformation is the evidence of visible/fundamental change in the shape/form/performance of the organisation. It can also be termed breakthrough improvement which impacts product, people, process and technology and ultimately delivers superior organisational performance, led from the top.

Continuous improvement or Kaizen delivers small incremental improvements on a regular basis that cumulatively yields improvement and can be initiated and deployed by those empowered to do so in the organisation. The difference between transformation and continuous improvement perplexes people as it is often used interchangeably. One could pose a question as to whether the difference matters?

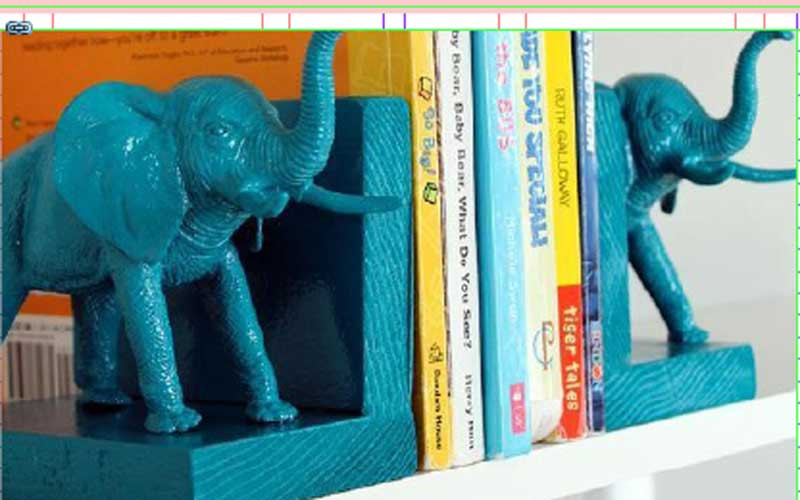

However, I posit that is not the right question, instead we should understand the nature of the relationship between the two. Continuous improvement can be described as bookends to transformation where it can be a precursor but must be central to its sustainability post-implementation.

To explore this relationship we look back at the forerunners of transformation.

Forerunners of transformation

If you have worked in operations, you will be familiar with TQM (Total Quality Management) which originated in Japan in the 1950s.

The philosophy is that quality is everyone’s responsibility, with a focus on detecting and eliminating errors to ensure that customer expectations are continually met.

Then came Lean manufacturing, originating from the Toyota Production System with a focus on eliminating waste in processes to increase efficiency. The seven types of waste were classified as;

- Overproduction

- Inventory

- Motion

- Overprocessing

- Defects

- Overproduction

- Waiting

In 1984 Six Sigma originated from Motorola and was popularised by Jack Welch, General Electric CEO in 1985.

It focuses on reducing process variation utilising process data and analysing it statistically to improve process controls and therefore quality.

Six sigma is defined as 3,4 defects per million units produced i.e. producing defect free products 99,99966% of the time which is near perfection — but not always practical! It must be noted that Implementing Six sigma is costly and it was important that prior to adopting this approach, the organisation fully understood the customer needs first to determine the acceptable level of process variation. Business Process re-engineering was first published by Michael Hammer in 1990 describing the need for a radical redesign of end-to-end business processes leveraging technology and data to achieve breakthrough results.

It included cross-functional teams as the core business processes cut right across the organisation.

Instead of merely improving the current process an organisation would challenge itself to redesign a process carte blanche applying what they knew about customer needs, the organisation and their competitive landscape.

Over time Lean and Six Sigma were combined to create what is now popularly termed Lean Six Sigma which focuses on how to improve customer satisfaction by reducing process variation (six sigma) and eliminating waste (lean) in processes.

All these tools and frameworks focused primarily on process, which is simply how we deliver value to customers. Transformation expands on this encompassing product, people and technology.

The evolution of transformation

As technology adoption gained momentum organisations recognised that deploying new systems and applications increasingly rendered some processes obsolete, whilst others required process re-engineering because of automation.

The knock-on effect was an eradication of roles as certain skill sets were no longer required. Reduction in manual interventions and the number of process steps also required less people. The people impact led to retrenchments, retraining or redeployment within the organisation.

We can all relate to the transformation I previously discussed about the banking sector. With the move to online and telephone banking driven by technology changes (digital transformation), banking is mostly a self-service model resulting in a significantly reduced physical branch network requiring less customer facing employees.

Conversely, there is increased demand for technology skills as the banks continue to improve this self-service operating model to give the customers a seamless customer experience.

The development of new products or services at accelerated rates required human resources with a different mindset and a new skill set. How was an organisation expected to develop or acquire new capabilities at a pace never seen before in the face of market disruption?

Such was the conundrum facing well established organisations.

Those with the financial muscle identified that one of the quickest ways to overcome this gap was through acquisition of start-ups that had built successful businesses around these desired capabilities.

Having recognised change in consumer behaviour from watching traditional tv to consuming online video content, Google developed a platform called Google Videos for sharing video content.

It was competing with YouTube which was growing in popularity at a much faster rate. In 2006 Google acquired YouTube which then provided it with a platform to grow its ad business and therefore advertising revenue which is upwards of $20 billion annually. Today YouTube is the largest video search engine and second largest search engine in the world.

It is now evident that for a technology change to be implemented successfully it had to be accompanied by process and people changes.

Signalling a need to develop a new operating model to fully realise its benefits.

Adopting this integrated approach delivered breakthrough improvements inferring a competitive advantage and tangible step change in organisational performance in metrics such as revenue growth, customer growth, improved NPS (net promoter score) and customer satisfaction and shortened speed to market.

Breakthrough improvements are transformative in nature. Organisations with a continuous improvement approach have inculcated a culture of customer-first in innovation (new ideas, identifying new opportunities), never being satisfied with the status quo (growth mindset) and having a problem-solving mindset.

Where this is instilled the need to embark on transformation is quickly identified. Additionally the likelihood of delivering a successful transformation is higher and minimises performance regression. Continuous improvement can therefore be described as “bookends” to transformation, acting as its precursor and subsequent sustainer of superior business performance.

- Muguti is a strategy and transformation consultant, a Lean Six Sigma Black Belt Practitioner who has successfully initiated, led and delivered Transformation programmes across various industries and global blue-chip organisations. — +263 783 533938, [email protected], LinkedIn https://www.linkedin.com/in/nyari-muguti-24998017.